Dippy-eggs and toast soldiers for breakfast? M&S ham salad sandwich for lunch? Do you ever wonder where the bread came from to create such traditional British culinary delights… well it is more than likely that it is all thanks to the Chorleywood Experiment.

During the 1960s when US scientists were involved in some serious research into how to conquer space and deliver a man to the moon, the finest scientists in ‘Good Ole Blighty’ were given a much more important task… to invent a new sort of bread.

Dippy-eggs and toast soldiers

Dippy-eggs and toast soldiers

Bread has been a staple part of the English diet for millennia. In ancient England as the thick forests were cleared to make way for arable farming, the open countryside as we know it today began to emerge. And with the rich soil and endless rain in the warmer counties of southern England the gluten-rich wheat would thrive that could be milled and made into the softest of bread. Further north, in a line roughly defined by the rivers of the Severn and Humber, tougher crops such as barley and oats, which needed less sunlight were grown.

The ‘Staff of Life’ was considered so important in medieval England that Henry III’s Assizes in 1266 set down a law that regulated the weight and quality of a standard loaf to be sold in the villages and towns of his realm. The same law also covered that other essential of medieval life… ale! This ensured that the great unwashed could afford two pounds of wheat, enough for one loaf, and a gallon of ale each day.

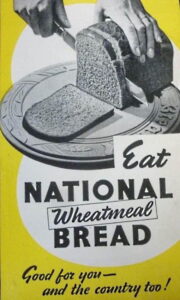

During the Second World War however, the great unwashed were forced to endure the so-called ‘National Loaf’. The National Loaf was introduced in Britain in 1942 as part of the rationing scheme, and was a rather grey, crumbly bread made with National Flour. As supplies of wheat were limited during the war white bread was banned.

The National Loaf, photo courtesy of Family at War re-enactment group

The National Loaf, photo courtesy of Family at War re-enactment group

White bread is made by milling the whole grain and sifting out the bran and wheatgerm, and as a consequence, less flour is made. The National Loaf was made using all available ingredients, the Ministry of Food also added extra calcium and other vitamins to ensure the health of the nation. They also stipulated that the National Loaf could only be sold the day after it was baked. The logic behind this was that it could be sliced thinner if it was slightly stale and therefore you could get more slices from your loaf.

Image courtesy of Doing Their Bit. Please click here for a recipe for the National Loaf.

In the years following the war however, as society began to return to some sort of normality, the government recognised the need for a new sort of bread… a bread that could be mass-produced… that would last forever… that was tasty and best of all… that was cheap. This is where Chorleywood came in.

For those folk who don’t know where Chorleywood is, the town sits on the western edge of London just outside the M25 Motorway network. Back in the 1960s however, Chorleywood was the home of the British Baking Industries Research Association (BBIRA). Although this august organisation no longer exists, it was to be at the very heart of a major dietary revolution.

In the extensive grounds of Choleywood Lodge, a crack team of 130 food scientists were assembled and instructed to invent a new type of bread. In a programme jointly funded by the post-war government and the three baking giants of Allied Bakeries, Rank-Hovis-Macdougall and Spillers, the scientists pursued their quest of producing a soft fluffy loaf by testing new ingredients in new combinations and using innovative machines. And so it was in 1961, that those dedicated boffins developed the Chorleywood Bread Process (CBP).

Traditionally bread had been made from wheat flour by manually kneading dough and adding a raising agent, typically yeast, and then leaving to ferment before finally baking it. The CBP significantly reduced this processing time. By adding more yeast, water and fat, as well as some Vitamin C, and then subjecting the dough to intense mechanical working by high-speed mixers, the Chorleywood boffins boasted that they could turn a sack of wheat into a sliced and packaged loaf in about three and a half hours.

It is indeed true to say that the Chorleywood Bread Process revolutionised the bread making industry, as in 2009, it was determined that approximately 80% of all the bread made in Britain, Australia, New Zealand and India, used the process. In addition, the CBD has been adopted in more than 30 other countries across the globe.

And so in conclusion, whilst we Brits may have failed in getting a man onto the moon we can thank our brilliant scientists and console ourselves by buttering some fine Chorleywood toast soldiers before immersing them into our soft-boiled dippy-eggs.

Published 22nd August 2023.